A286

View AMS Numbers >

Stainless Steel A286

Stainless Steel A286 is a precipitation-hardenable super-alloy based on iron. The material finds use in applications requiring high strength, paired with corrosion resistance up to 1300 °F (700 °C). Besides, the alloy has other favorable properties, including excellent fabrication characteristics, low-temperature non-magnetic strength [down to -320 °F (-196 °C)], and ductility.

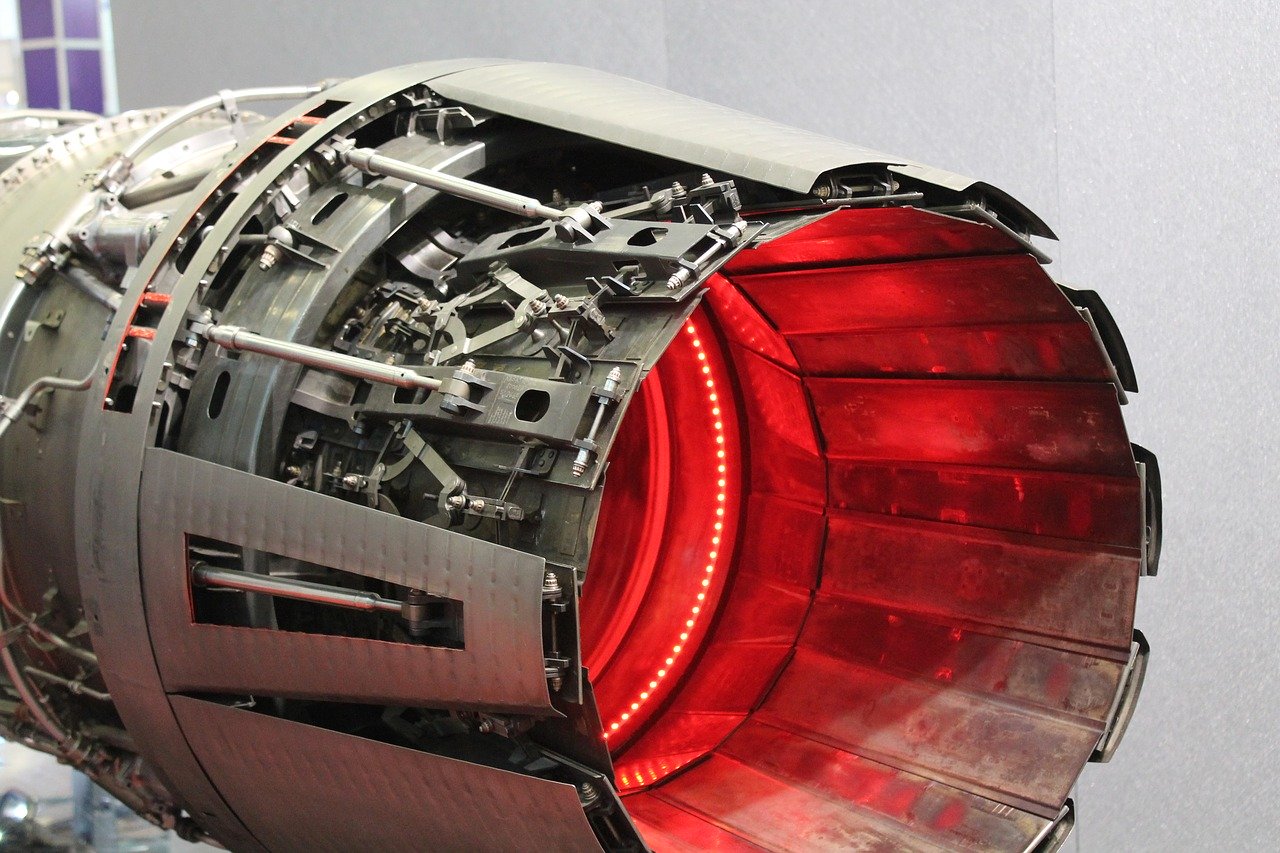

Thanks to its unique properties, Stainless Steel finds use in various aircraft components, including jet engine components, fasteners, and springs. Moreover, the material is used in industrial gas turbines, aqueous solutions with moderate corrosion properties, and non-magnetic cryogenic parts. Other applications include high-temperature afterburner parts, tanks, piping, pumps, heat exchangers, and superchargers in the automotive industry.

Meanwhile, despite the fact that A286 is harder than similar nickel or cobalt-based stainless steel, it can be easily machined and formed by cold-drawing. Furthermore, depending on the application, A286 can be solution annealed or age-hardened, while additional cold-working elevates the creep strength substantially.

Tech Steel & Materials offers Stainless Steel A286 in twelve sub-type specifications and multiple shapes/forms:

- AMS 5525 (Plate, Sheet, and Strip)

- AMS 5726 (Bar and Wire)

- AMS 5731 (Bar, Custom Tube, Forging, Ring, Tubing, and Wire)

- AMS 5732 (Bar, Custom Tube, Forging, Ring, Tubing, and Wire)

- AMS 5734 (Bar, Custom Tube, Forging, Tubing, Wire)

- AMS 5735 (Bar, Forging, Ring, Tubing)

- AMS 5736 (Bar, Forging, Ring, Tubing)

- AMS 5737 (Bar, Custom Tube, Forging, Tubing, Wire)

- AMS 5805 (Wire)

- AMS 5853 (Bar and Wire)

- AMS 5858 (Plate, Sheet, and Strip)

- AMS 5895 (Bar, Custom Tube, Forging, Ring, Tubing, and Wire)

Tech Steel & Materials also offer a fully customized line of tube drawing and seamless tube for Stainless Steel A286. Learn more about our custom tubing services: Customized Tubing Services

Chemical Composition of Stainless Steel A286

| Element | Min (%) | Max (%) |

| Carbon, C | – | 0.08 |

| Manganese, Mn | 8 | 2 |

| Silicon, Si | – | 1 |

| Sulfur, S | – | 0.025 |

| Phosphorus, P | – | 0.025 |

| Chromium, Cr | 13.5 | 16 |

| Titanium, Ti | 1.9 | 2.35 |

| Nickel, Ni | 24 | 27 |

| Molybdenum, Mo | 1 | 1.5 |

| Vanadium, V | 0.1 | 0.5 |

| Aluminum, Al | – | 0.35 |

| Boron, B | 0.003 | 0.010 |

| Iron, Fe | – | *Balance |

*Not exclusively to the element mentioned, but that one predominates other elements that are used only in minimal quantities.

Fabrication and Working Instructions

Thanks to its good ductility, Stainless Steel A286 can be cold-worked and formed using common practices. That said, it’s best to form the parts in the solution annealed condition.

Moreover, the alloy can be readily machined using standard methods and carbide inserts, similarly to austenitic steels.

Meanwhile, you can use regular welding procedures on A286, including gas tungsten arc, gas metal arc, and shielded metal arc. Using a welding wire of the same specification is preferable, but a nickel-based filler metal would work as well. For optimal results, the weld bead should be raised, and the material in the solution annealed condition. A286 is susceptible to cracking if welded in the aged condition.

Maximum strength can be achieved by solution treating, followed by cold working and aging is recommended.

Physical Properties

| Property | Imperial | Metric |

| Specific Gravity | 7.92 | 7.92 |

| Specific Heat | 10 Btu/lb.-°F | 420 Joules/kg-K |

| Density | 0.286 lb/in3 | 7.92 g/cm3 |

| Melting Range | 2500 – 2600 °F | 1370 – 1430 °C |

| Magnetic Permeability | 1.01 | 1.007 |

| Linear Coefficient of Thermal Expansion (70 °F to 200 °F) (21 °C to 93 °C) |

9.17 [10(-6)/°F] | 16.5 [10(-6)/K] |

| Linear Coefficient of Thermal Expansion (70 °F to 400 °F) (21 °C to 204 °C) |

9.35 [10(-6)/°F] | 16.8 [10(-6)/K] |

| Linear Coefficient of Thermal Expansion (70 °F to 600 °F) (27 °C to 316 °C) |

9.47 [10(-6)/°F] | 17 [10(-6)/K] |

| Linear Coefficient of Thermal Expansion (70 °F to 800 °F) (21 °C to 427 °C) |

9.64 [10(-6)/°F] | 17.4 [10(-6)/K] |

| Linear Coefficient of Thermal Expansion (70 °F to 1000 °F) (21 °C to 538 °C) |

9.78 [10(-6)/°F] | 17.6 [10(-6)/K] |

| Linear Coefficient of Thermal Expansion (70 °F to 1200 °F) (21 °C to 649 °C) |

9.88 [10(-6)/°F] | 17.8 [10(-6)/K] |

| Linear Coefficient of Thermal Expansion (70 °F to 1400 °F) (21 °C to 760 °C) |

10.32 [10(-6)/°F] | 18.6 [10(-6)/K] |

| Thermal Conductivity (@ 302 °F) (@ 150 °C) |

8.7 Btu/(hr/ft²/in/°F) | 15.1 [W/m-K] |

| Thermal Conductivity (@ 572 °F) (@ 300 °C) |

10.3 Btu/(hr/ft²/in/°F) | 17.8 [W/m-K] |

| Thermal Conductivity (@ 932 °F) (@ 500 °C) |

12.6 Btu/(hr/ft²/in/°F) | 21.8 [W/m-K] |

| Thermal Conductivity (@ 1112 °F) (@ 600 °C) |

13.8 Btu/(hr/ft²/in/°F) | 23.9 [W/m-K] |

| Shear Modulus (annealed) at 450 °F (232 °C) | 11000 ksi | 75.8 GPa |

| Magnetic Permeability (Solution Treated) |

1.010 | 1.010 |

| Magnetic Permeability (Solution Treated and Aged) |

1.007 | 1.010 |

Mechanical Properties (Solution Heat Treated at Room Temperature)

| Property | Imperial | Metric |

| Ultimate Tensile Strength | 89,000 psi | 620 MPa |

| Yield Strength | 39,900 psi | 275 MPa |

| Elongation at Break | 40% | 40% |

| Modulus of Elasticity | 29,200 ksi | 201 GPa |

| Poisson’s Ratio | 0.3 | 0.3 |

| Shear Modulus | 11,200 ksi | 77 GPa |

| Reduction of Area | 20% | 20% |

| Elongation in 4D | 15% | 15% |

Heat Treatment

The usual heat treatment for developing high-strength A286 parts starts with solution annealing at 1800 °F (980 °C), followed by oil quenching. Then, hold the alloy at 1325 °F (720 °C) for 16 hours and air cool.

Tech Steel & Materials

Tech Steel & Materials