Stainless Steel 17-4PH

View AMS Numbers >

Stainless Steel 17-4PH

17-4PH is a widely-used martensitic precipitation-hardening stainless steel with a high concentration of chromium and nickel. It has many favorable properties, including excellent strength, good corrosion resistance, and excellent mechanical properties up to 600 °F (316 °C).

The alloy also possesses good toughness when welded, while short low-temperature heat treatments reduce warping and scaling. Additionally, 17-4PH is easy to machine and fabricate.

Thanks to the beneficial properties, 17-4PH finds use in various industries. Typical parts include mechanical seals, oil patch, and pump shafts.

Furthermore, the alloy also finds use in the aerospace industry, petroleum industry, and chemical industry, food processing equipment, paper and pulp industry, nuclear waste processing and storage, and general metalworking.

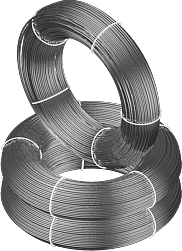

Tech Steel & Materials offers Stainless Steel 17-4PH in two sub-type specifications and multiple shapes/forms:

Stainless Steel 17-4PH Chemical Composition

| Element | Min (%) | Max (%) |

| Carbon, C | – | 0.07 |

| Manganese, Mn | – | 1 |

| Silicon, Si | – | 1 |

| Sulfur, S | – | 0.03 |

| Phosphorus, P | – | 0.04 |

| Chromium, Cr | 15 | 17.5 |

| Niobium + Tantalum, Nb + Ta | 0.15 | 0.45 |

| Nickel, Ni | 3.0 | 5.0 |

| Copper, Cu | 3.0 | 5.0 |

| Iron, Fe | – | *Balance |

*Not exclusively to the element mentioned, but that one predominates other elements that are used in smaller quantities.

Fabrication and Working Instructions

Stainless Steel 17-4PH reacts best to hot forming at 1742 to 2192 °F (950 to 1200 °C), with annealing at 76 °F (25 °C) and aging. The alloy can also be cold-formed in limited form, primarily to plates in the annealed condition. However, stress corrosion resistance can be improved with re-aging.

Furthermore, 17-4PH can be cut using mechanical operations, such as abrasive waterjets, machining, bandsaw, and shearing. However, plasma cutting isn’t recommended on this alloy.

17-4PH has the best welding characteristics of competing stainless steel alloys. Moreover, it can be welded using all standard techniques, including gas tungsten arc, gas metal arc, shielded metal arc, and plasma arc. To achieve desired mechanical properties, pre-weld and post-weld heat treatments are recommended. For the best results, we recommend the AMS 5643 wire.

Physical Properties of Stainless Steel 17-4PH

| Property | Imperial | Metric |

| Melting Range | 2560-2625 °F | 1404-1440 °C |

| Specific Heat | 0.11 Btu/lb.-°F | 460 Joules/gg-K |

| Specific Density | 0.282 lb/in3 | 7.8 g/cm3 |

| Electrical Resistivity | 38.6 µΩ in | 98 µΩ cm |

| Linear Coefficient of Thermal Expansion (70 °F to 200 °F) (21 °C to 93 °C) | 6 [in/in/°F·106] | 10.8 [μm/m·°C] |

| Linear Coefficient of Thermal Expansion (70 °F to 400 °F) (21 °C to 204 °C) | 6 [in/in/°F·106] | 10.8 [μm/m·°C] |

| Linear Coefficient of Thermal Expansion (70 °F to 600 °F) (27 °C to 316 °C) | 6.2 [in/in/°F·106] | 11.2 [μm/m·°C] |

| Linear Coefficient of Thermal Expansion (70 °F to 800 °F) (21 °C to 427 °C) | 6.3 [in/in/°F·106] | 11.2 [μm/m·°C] |

| Thermal Conductivity (@ 300 °F) (@ 149 °C) | 124 Btu/(hr/ft²/in/°F) | 17.9 [W/m-K] |

| Thermal Conductivity (@ 500 °F) (@ 260 °C) | 135 Btu/(hr/ft²/in/°F) | 19.5 [W/m-K] |

| Thermal Conductivity (@ 860 °F) (@ 460 °C) | 156 Btu/(hr/ft²/in/°F) | 22.5 [W/m-K] |

| Thermal Conductivity (@ 900 °F) (@ 482 °C) | 157 Btu/(hr/ft²/in/°F) | 22.6 [W/m-K] |

| Poisson’s Ratio (H900 Condition) | 0.272 | 0.272 |

| Modulus of Elasticity (H900 Condition) | 28 x 106 ksi | 197 x 103 MPa |

| Modulus of Rigidity in Torsion | 9.68 x 103 ksi | 67 x 103 MPa |

Stainless Steel 17-4PH Mechanical Properties

| Property | Imperial | Metric |

| Ultimate Tensile Strength | 23,300 psi | 160 MPa |

| Yield Strength (0.02%) | 16,680 psi | 115 MPa |

| Elongation (% in 2’’) | 5% | 5% |

| Rockwell Hardness C | 35 | 35 |

Heat Treatment

Stainless Steel 17-4PH is available in the solution annealed condition at 1900 °F (1038 °C) and then air-cooled to 90 °F (32 °C).

However, additional heat treatments can produce various hardness and toughness levels. The most common treatments are listed in the table below.

| Condition | Temperature [± 15 °F (± 8.4 °C)] | Cooling Method and Duration |

| H 900 | 900 °F (482 °C) | Air cooling for 1 hour |

| H 925 | 925 °F (496 °C) | Air cooling for 4 hours |

| H 1025 | 1025 °F (551 °C) | Air cooling for 4 hours |

| H 1075 | 1075 °F (580 °C) | Air cooling for 4 hours |

| H 1100 | 1100 °F (593 °C) | Air cooling for 4 hours |

| H 1150 | 1150 °F (621 °C) | Air cooling for 4 hours |

| H 1150 + 1150 | 1150 °F (621 °C) followed by 1150 °F (621 °C) |

Air cooling for 4 hours followed by Air cooling for 4 hours |

| H 1150-M | 1400 °F (760 °C) followed by 1150 °F (621 °C) |

Air cooling for 2 hours followed by Air cooling for 4 hours |

Select AMS Number:

| AMS Number | Alloy | Type | UNS | Cross Ref. Spec | Misc./Shape | |

|---|---|---|---|---|---|---|

| AMS 5604 Plate | 17-4PH | Stainless Steel | S17400 | - | Plate |

|

| AMS 5604 Sheet | 17-4PH | Stainless Steel | S17400 | - | Sheet |

|

| AMS 5604 Strip | 17-4PH | Stainless Steel | S17400 | - | Strip |

|

| AMS 5643 Bar | 17-4PH | Stainless Steel | S17400 | - | Bar |

|

| AMS 5643 Forging | 17-4PH | Stainless Steel | S17400 | - | Forging |

|

| AMS 5643 Ring | 17-4PH | Stainless Steel | S17400 | - | Ring |

|

| AMS 5643 Tubing | 17-4PH | Stainless Steel | S17400 | - | Tubing |

|

| AMS 5643 Wire | 17-4PH | Stainless Steel | S17400 | - | Wire |

|

Tech Steel & Materials

Tech Steel & Materials