Stainless Steel A286 AMS 5525

AMS 5525 is a sub-type specification of Stainless Steel A286. The alloy possesses many favorable properties, including high strength at elevated temperatures, excellent corrosion resistance up to 1300 °F (700 °C), good fabrication properties, and low-temperature non-magnetic strength.

The AMS 5525 specification is solution heat-treated at 1800 °F (980 °C), followed by oil quenching, and holding for 16 hours at 1325 °F (720 °C). Tech Steel & Materials offers this specification in plates, sheets, and strips. The strength of the alloy can be further increase by solution treating, followed by cold working and aging.

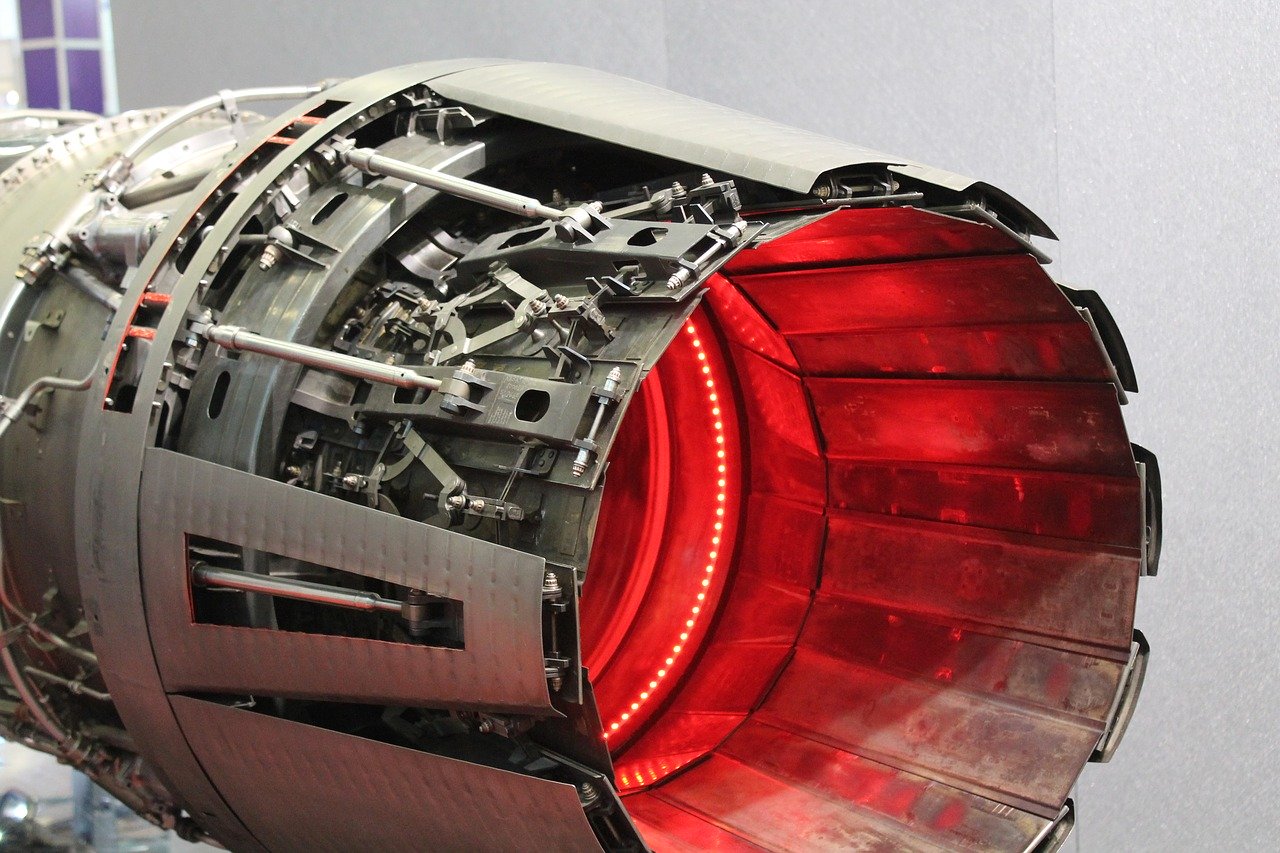

Thanks to the excellent strength at elevated temperatures, AMS 5525 parts find use in various applications, including aircraft jet engine components, fasteners and springs in high-temperature environments, and industrial gas turbines.

Moreover, the corrosion resistance makes it useful in aqueous solutions with moderate corrosion properties (acetic acid, nitric acid, salt spray). Ultimately, AMS 5525 can also be utilized for non-magnetic cryogenic parts, thanks to the excellent low-temperature strength, down to -320 °F (-196 °C).

Compared to similar cobalt and nickel stainless steel, AMS 5525 can be formed and cold-worked more easily. Meanwhile, the alloy can be welded using standard procedures, gas tungsten arc, gas metal arc, and shielded metal arc. For best results, it’s best to weld the parts in the annealed condition. Otherwise, a cracking might appear. Also, a convex weld fetches optimal results.