Stainless Steel A286 AMS 5737

AMS 5737 is a sub-type specification of Stainless Steel A286, a precipitation-hardenable super-alloy with high strength at elevated temperatures, good corrosion resistance up to 1300 °F (700 °C), and excellent non-magnetic strength at cryogenic temperatures, down to -320 °F (-196 °C).

Tech Steel & Materials offers the AMS 5737 specification in the form of bars, custom tubes, forging, tubing, and wire. This specification comes in a solution treated and aged condition. The alloy is first subjected to a temperature of 1650 °F (900 °C) for one hour, then water or oil quenched. For additional precipitation heat treatment, hold heat to 1300-1400 °F (704-760 °C) and hold for 16 hours. Then, air cool to room temperature. The resulting hardness ranges from 277 to 363 HB.

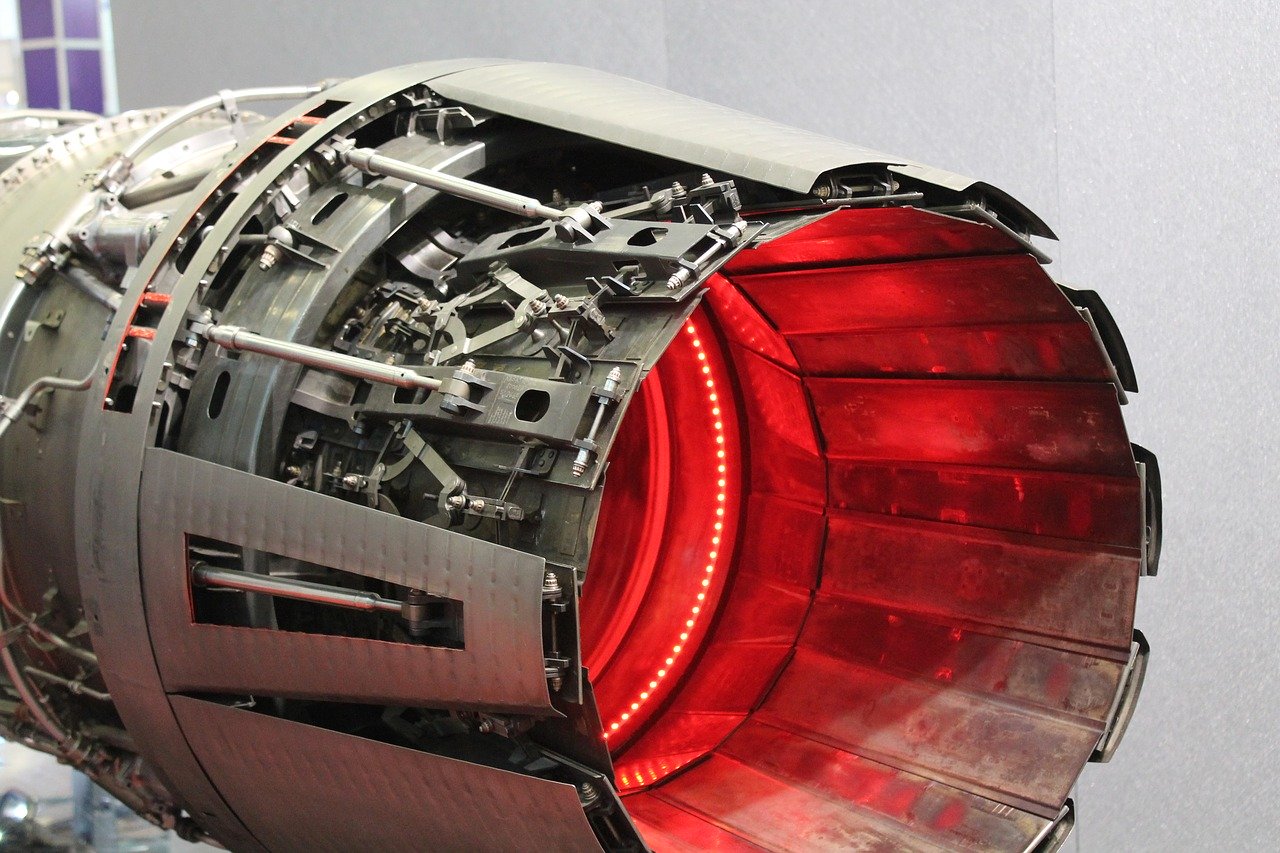

Thanks to the beneficial properties, AMS 5737 finds use in jet engines, superchargers, and industrial gas turbines, specifically for rotors, shafts, and blades. Furthermore, this specification is used for high-temperature afterburner parts, tanks, piping, pumps, and heat exchangers.

Despite the high hardness, the alloy can be readily formed and cold-worked, increasing creep strength. Meanwhile, the alloy can be welded using gas tungsten arc, gas metal arc, and shielded metal arc procedures. That said, special care should be applied, since cracking may occur on parts in the aged condition, such as the AMS 5737.