Revolutionizing Titanium Alloys: Utilizing Oxygen and Iron for Enhanced Strength and Sustainability

Scientists have successfully created a novel category of titanium alloys that possess remarkable strength and resistance to brittleness when subjected to tension. This achievement was accomplished through a combination of innovative alloy compositions and advanced 3D-printing techniques.

Research has the potential to expand the range of applications for titanium alloys, and enhance sustainability efforts.

This advancement has the potential to revolutionize applications across diverse sectors, most notably in aerospace and energy. Moreover, it can significantly contribute to sustainability initiatives by producing these alloys using industrial waste and low-grade materials. This will also help in reducing waste and maximizing resource utilization, further promoting a more environmentally conscious approach to alloy production.

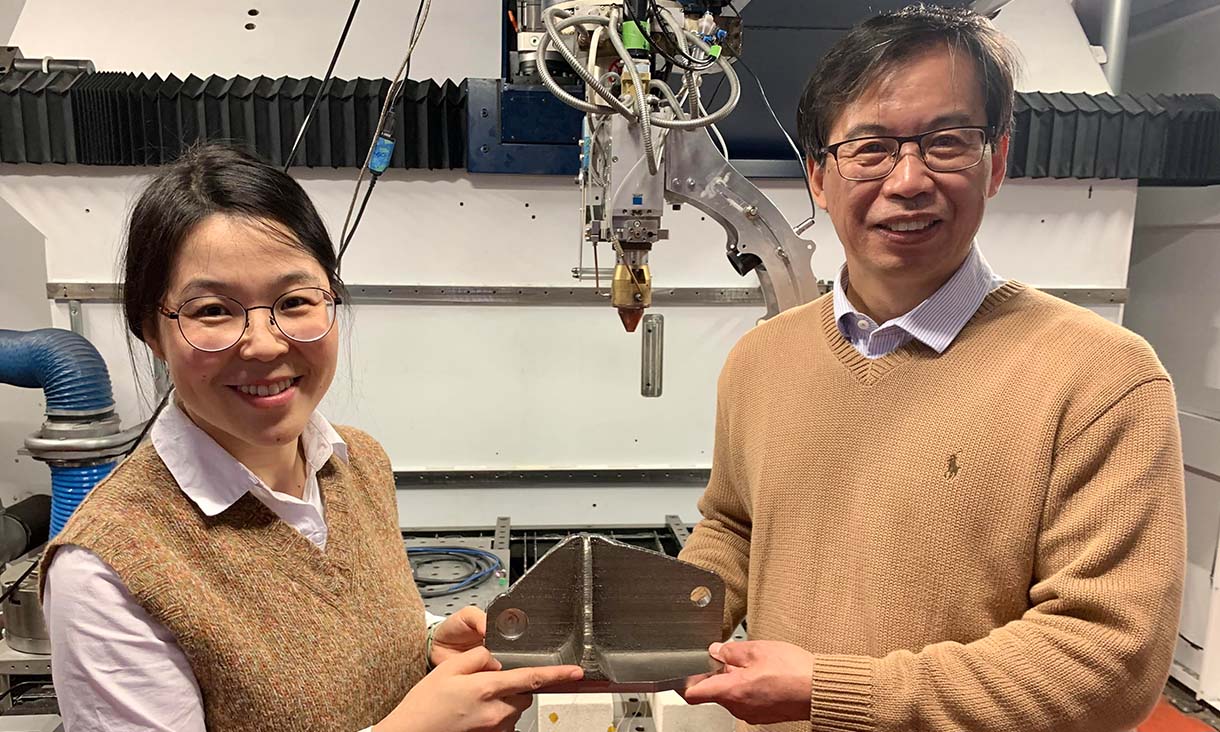

The research team responsible for this breakthrough includes esteemed researchers from RMIT University and the University of Sydney.

Researchers have developed a remarkable titanium alloy using 3D printing and metal powder.

The newly developed titanium alloys comprise two forms of titanium crystals, namely the alpha-titanium phase and the beta-titanium phase. Traditionally, these alloys have relied on the addition of aluminum and vanadium to titanium for their production.

For developing this new alloy, researchers explored the use of oxygen and iron, which are abundant and cost-effective resources. This innovative approach aims not only to enhance the strength and ductility of these titanium alloys but also to open up new possibilities for their application in various industries.

The research is published in the journal Nature.

Article Source: Industry Tap

Tech Steel & Materials

Tech Steel & Materials

Comments are closed