10 Facts About the Nickel Element

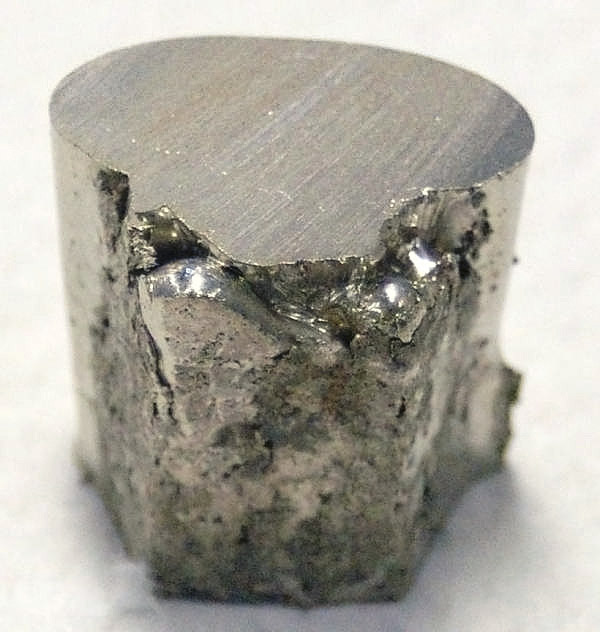

Nickel (NI) is among the most abundant materials on Earth. It’s also among the most widely used material on the planet. Most nickel is located in the planet’s core, more than 1800 miles beneath the Earth’s crust. A silvery-white material with a slight gold tinge, nickel has a relative atomic mass of 58.69, a density of 8.9g / cm³, and a melting point of 1455°C. Its boiling point is 2730°C. This versatile, ductile material finds wide use in industry because of its hardness, good ductility, and magnetic and corrosion resistance. Plus, it can be highly polished for specific purposes.

Number 28 on the Periodic Table, nickel was identified and isolated as an element in 1751 by Baron Axel Fredrik Cronstedt. The Swedish mineralogist and chemist called the element kupfernickel because he found it in a rock that resembled copper (kuper) ore and because miners thought that the rock’s evil spirits (nickel) were making it hard to extract its copper. Today, nickel is used in everything from coins, batteries, jet engines, and optical instruments to medical equipment, electric stoves, and machinery, and everything in between. Nickel is also an essential trace element found in some animals. Without it, they’d die.

Ten Facts about Nickel

Below are ten little-known facts about nickel:

- Two-thirds of the primary nickel ore mined goes into stainless steel.

- Nickel is one of three elements ferromagnetic at room temperature.

- The world’s nickel is estimated at almost 300 million tons.

- Most nickel is used in alloys, including stainless steel (65%), and heat-resistant alloys and non-ferrous alloys (20%).

- The U.S. five-cent coin is only 25% nickel but 75% copper by weight.

- Nearly 80% of the nickel historically mined was extracted in the last three decades.

- Australia, Indonesia, South Africa, Russia, and Canada account for more than 50% of the global nickel resources.

- Beer kegs made of nickel-based stainless steel often stay in use for 30-40 years.

- Nearly 80% of the pure nickel used in the U.S. finds its way into alloys.

- Nickel is 100 times more concentrated below the Earth than in it.

Is Nickel Alloy Magnetic?

Nickel is one of four ferromagnetic materials, along with iron, cobalt, and gadolinium. Ferromagnetism is the strongest type of magnetism, along with the similar effect of ferrimagnetism. Nickel has a higher susceptibility to magnetization than many other materials. The strength of the materials magnetism depends on the applied magnetizing field. The magnetization may remain even after removing the applied field. Iron is an excellent example of this effect and is associated with the parallel magnetic alignment of neighboring atoms.

Nickel’s magnetism is high because of the parallel alignment of dipoles. However, its magnetism changes after the Curie temperature (T C) or Curie point, which in nickel’s case is 358°C (676°F). It then stops being ferromagnetic magnetic and becomes paramagnetic. That means it becomes weakly attracted to a magnet’s poles without retaining any permanent magnetism. Nickel’s magnetic moments, which refer to a material’s magnetic strength, are smaller but stronger and healthier than iron’s are.

Nickel’s Use in Alloys

Few things are made from pure nickel. Instead, it’s combined with other materials to create alloys. An alloy’s composition is the key to its being attracted by a magnet. Alloys having a content of 72% to 83% have the best soft magnetic properties, which means you can easily magnetize and demagnetize a part made from this material. Mu-metal, for example, is a soft magnetic alloy comprising about 75% nickel and 15% iron, plus copper and molybdenum. This alloy has high permeability. That allows it to shield highly sensitive electronic equipment against static or low-frequency magnetic fields. Stainless steel alloys, however, can’t be attracted to a magnet.

Nickel is widely used as an alloy because of its resistance to high temperatures, corrosion, and rust, and other properties. Nickel-based alloys are used extensively in aviation, marine, chemical, electronics, medical and energy industries. Inconel° is a nickel-chromium alloy, for example, that provides excellent corrosion resistance at high temperatures. It’s used in a wide variety of products, including turbine engines, combustion chambers, turbine blades, color TV sets, and communication equipment.

Nickel is mined in more than 10 countries across the globe. So, the chances of there being a disruption in the material’s supply is low. These produce enough nickel to meet projected demand for nickel for many years to come. The United States, however, isn’t a source of nickel, since there are no active mines there.

Tech Steel & Materials

Tech Steel & Materials