GE Aviation Now Offering Metal Additives For Aircraft Engine Repair

GE Aviation Engine Services Singapore has become the first entity to offer metal additive technology for aerospace components, including aircraft engines. To put this simply, that would be 3D printed metal parts that are custom-crafted to the specific needs of the repair job and embedded or fitted where needed.

The idea is to offer custom parts quicker, reduce the cost of repairs by only manufacturing the specific component needed, and accommodate extraordinary needs or situations like fixing infrequent problems.

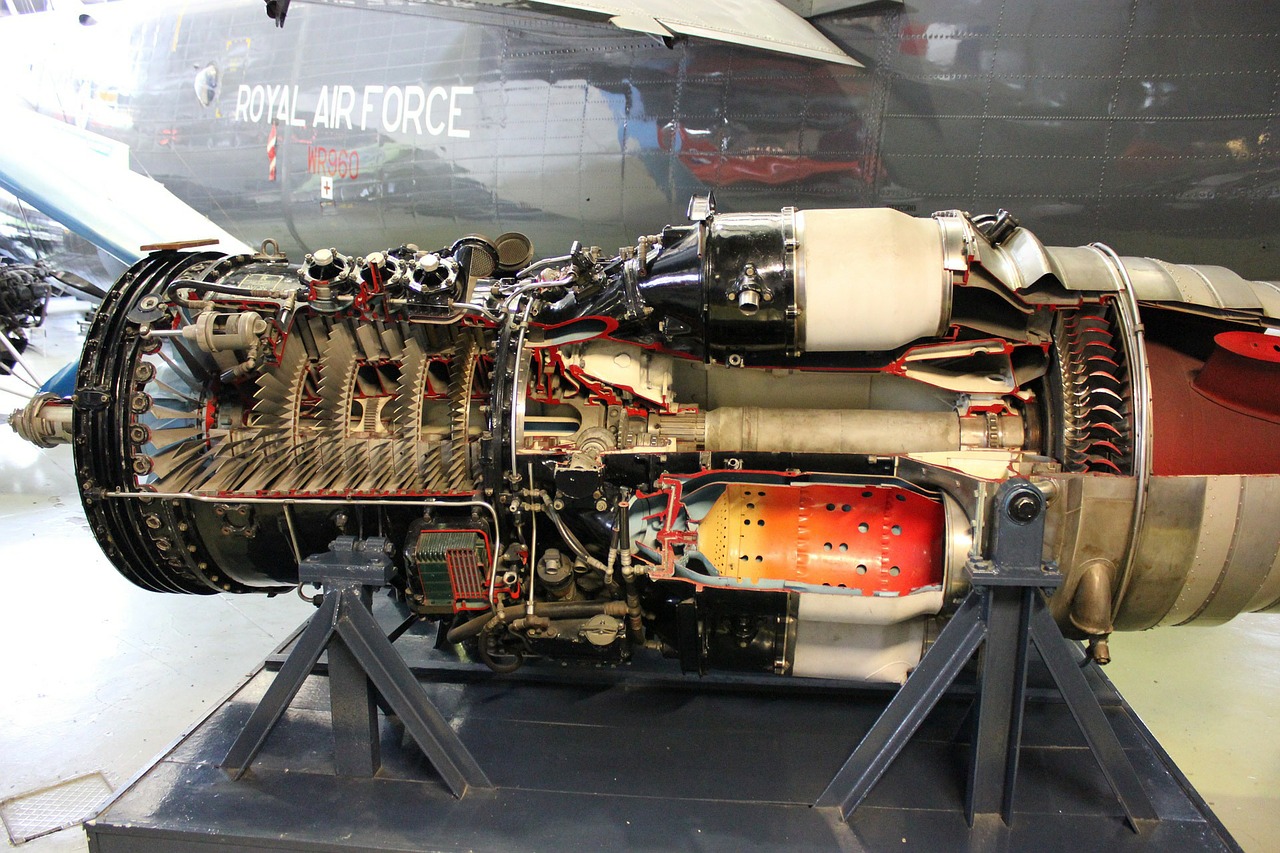

According to GE, its 3D printers, called Concept Laser M2 Series 5, can reduce the time it takes to repair parts inside CF6 engines, the company’s most widely used engine family, by up to 50%.

The particular engine family has proven to be so reliable, durable, fuel-efficient, and powerful, that it’s getting a second life fitted onto wide-body cargo aircraft, so it continues to operate for many more years than initially estimated. This creates unpredictable maintenance requirements and cases that only 3D printing can accommodate in a cost-feasible manner.

The M2 Series 5 can print aluminum alloys, titanium alloys, cobalt alloys, stainless steel, and nickels, so there are no limitations material-wise. The metals are used in powder form, and the printer uses a powerful dual laser array of 1 kiloWatt each to sinter it and give it its final form.

As for whether the 3D printed pieces would last in the highly demanding applications of aircraft engines that involve extreme temperature ranges, GE claims to have tested repairing high-pressure compressor blades that run at very high speeds and tight clearances within aircraft engines, so there’s no doubt about it.

Previously, repairing these blade tips would demand cutting, welding, and grinding, but with laser printing, the firm’s engineers can create precisely the shape of the missing part and build new tips with perfect alignment and profile.

Tech Steel & Materials

Tech Steel & Materials