Machine Learning AI Is Used for the First Time to Predict Stainless Steel Behavior in Fittings

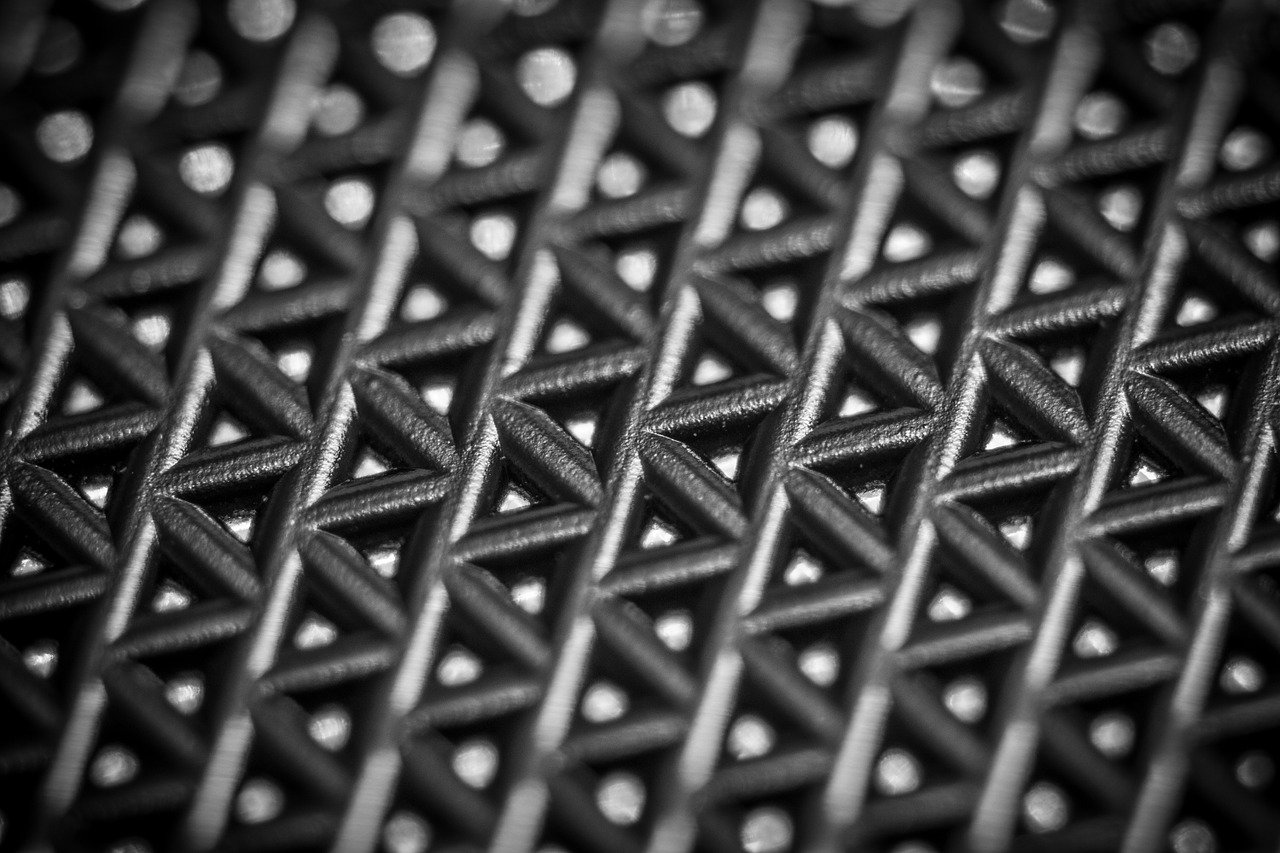

Researchers at the University of Illinois Urbana-Champaign became the first ever to deploy machine learning AI tools to evaluate the performance and behavior of different batches of stainless steel material under any circumstance. Not all stainless steel pieces are made equal, and when it comes to extreme applications, even the tiniest disparities in molecular structure could prove to be crucial differentiators between sustaining the load or cracking under pressure.

So far, engineers have relied upon central authorities and organizations conducting experiments or running extremely detailed physics models to supply tables of predictions that would be useful in the field. But these are cumbersome, don’t cover nearly enough use cases, and are often too generic to be useful in the context of cost-cutting and high-level optimization that underpins truly sophisticated designs.

As the leader of the team states, using machine learning to train a neural network and make these predictions without feeding it anything else rather than readily available experimental data solves all problems. This is the first time that someone uses AI to make predictions on what happens in a metal microstructure under various loading conditions.

By using this new tech, the team actually learned new things and was obliged to revise its understanding of others. In one loading and stress evaluation example in a polycrystalline metal, they figured that a single geometric parameter was so important that it determined the results 80% of the time. Physical differences between two grains adjacent to the boundary played a key role in only 20% of the time, which is way lower than what the researchers previously thought.

The model only works for certain things at the moment, but retraining it for a wider applications spectrum is always possible. The scientists want to incorporate it into existing failure models, something that would empower them beyond even the most in-depth analytical systems available right now. For this, they will need to expand to the grain interior, and they are already gathering experimental data for that.

Tech Steel & Materials

Tech Steel & Materials