Scientists Find Way to Produce Hydrogen using Water and Aluminum

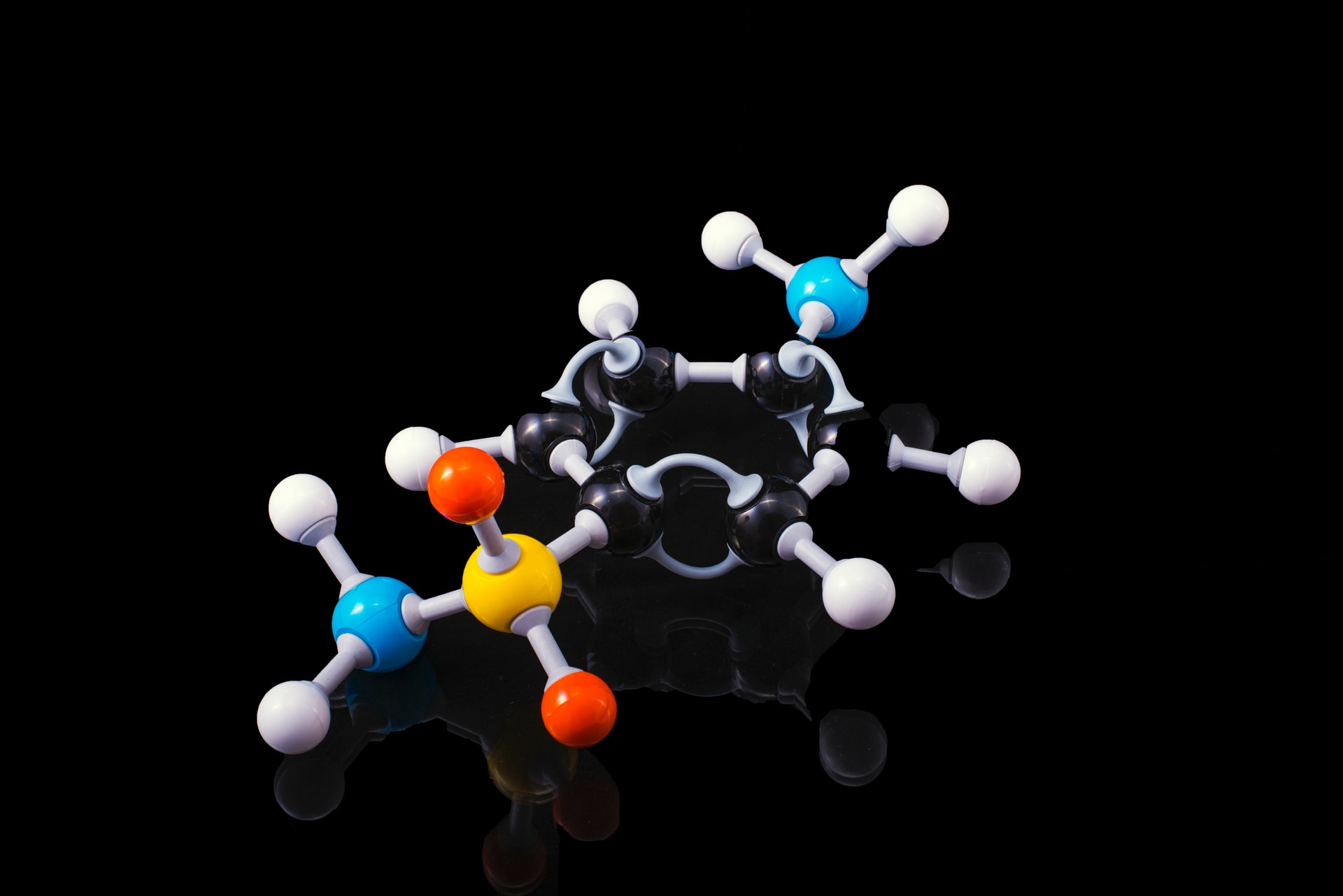

A team of researchers at UC Santa Cruz have found a cost-effective and practically feasible way to produce clean hydrogen gas by using water, aluminum, and gallium. Aluminum’s high level of reactivity has been known and well documented for many years, but researchers struggled to find an efficient way to put it into the context of hydrogen production.

The trick employed by the UC Santa Cruz team is to make a composite of gallium and aluminum, then derive nanoparticles of the latter, and eventually let it react with water at room temperature and atmospheric pressure. After the reaction is over, the entire quantity of the separated gallium can be recovered and recycled to be reused in the next hydrogen production cycle.

The role of gallium in the process is to remove the aluminum oxide coating that pacifies the reactivity between the metal and the water and prevents hydrogen gas generation. Through experimentation, the scientists found that a composite with a 3:1 ratio of gallium-aluminum works optimally for the purpose.

The hydrogen generation process doesn’t require any energy, either thermal or kinetic, and as shown in the video captured during home-based demonstrations, the reaction is rapid and requires no specialized or expensive equipment. Of course, the produced hydrogen isn’t captured in this case, as the video is just a proof of concept.

As the team explains, the composite can be prepared and stored for extended periods of time, requiring only some coverage with cyclohexane to keep moisture out. Also, the source of aluminum doesn’t have to be pure, as regular cans can be used without further processing.

On the other hand, gallium is a bit trickier to source and is also more expensive to buy, but because it can be retrieved and reused numerous times, the investment is well worth it. A cheap source of gallium would be the crushed powder of old semiconductors and low-melting fusible alloys.

Tech Steel & Materials

Tech Steel & Materials