What is Pipe Schedule?

Pipe Schedule (SCH) is a standard that measures the nominal wall thickness of a pipe, given by the ANSI / ASME B36.10M standard for Stainless Steel Pipe dimensions, and API 5L standard for seamless and welded steel pipes.

The pipe schedule number is non-dimensional and depends on the nominal pipe size, internal pipe working pressure, and the material used for the pipe wall.

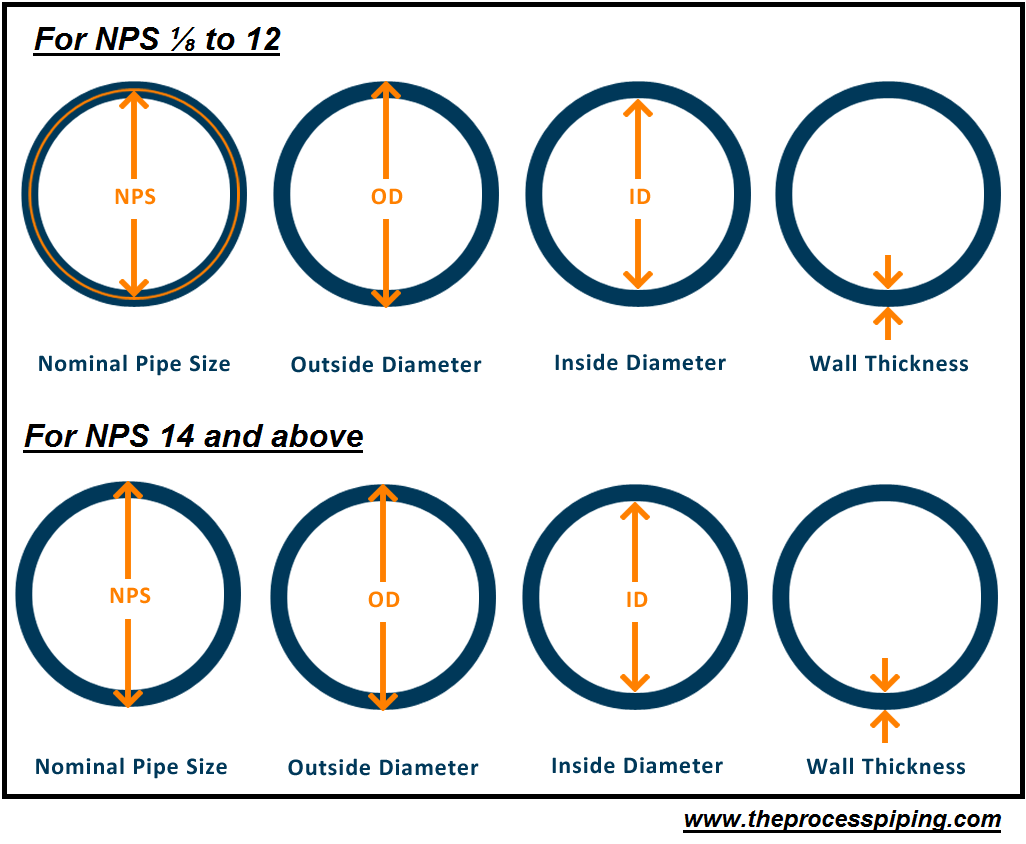

Image Credit: The Process Piping

Today, fourteen pipe schedule numbers are used: SCH 5, SCH 5S, SCH 10, SCH 10S, SCH 20, SCH 30, SCH 40S, SCH 60, SCH 80, SCH 80S, SCH 100, SCH 120, SCH 140, and SCH 160.

In the past, only three pipe wall thicknesses were used, but these measurements are very vague and aren’t used today

- Standard (STD)

- Extra Strong (XS)

- Double Extra Strong (XXS)

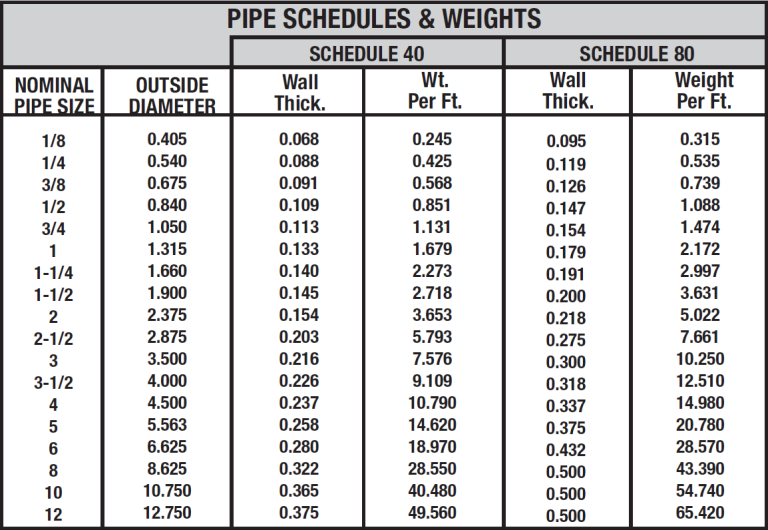

The most used pipe schedule is SCH 40. For NPS 12 or smaller pipes or pipes with outer diameter of around 12 inches, SCH 40 is the same wall thickness of the previously used value. The SCH 80 wall thickness, on the other hand, is the same as the previously used XS wall thickness for pipe sizes up to NPS 10.

The best way to see the relationship between pipe size, schedules and wall thicknesses is simply to refer to a conversion chart (below):

The following equation can be used to obtain the right pipe schedule for a given usage scenario:

SCH = (1,000) *(P/S), where P is the internal working pressure od the pipe, while S signifies how much stress the material can be subjected to.

Let’s have a look at an example of a pipe with internal working pressure of 450 psi and an S value of 12,000:

(1,000) *(450/12,000) = 37.5 or roughly equivalent to a SCH 40. Another essential thing to note is the alteration of the wall thickness depending on the NPS (Nominal Pipe Size). The larger the nominal diameter of the pipe, the thicker the wall becomes, even for the same SCH number. Let’s take the same SCH 40 wall thickness as before. For an NPS 1 pipe, an SCH 40 wall thickness is 0.133-inches, while for an NPS 2 pipe, the SCH 40 wall thickness is 0.154-inches.

Tech Steel & Materials

Tech Steel & Materials